Information

Hot melt edge banding machine suitable for application of coil material up to 2mm in thickness.

Traditional style edge banding machine but having a heavy duty chain driven feed system and benefitting from independent front and rear end trim saws.

Features include:

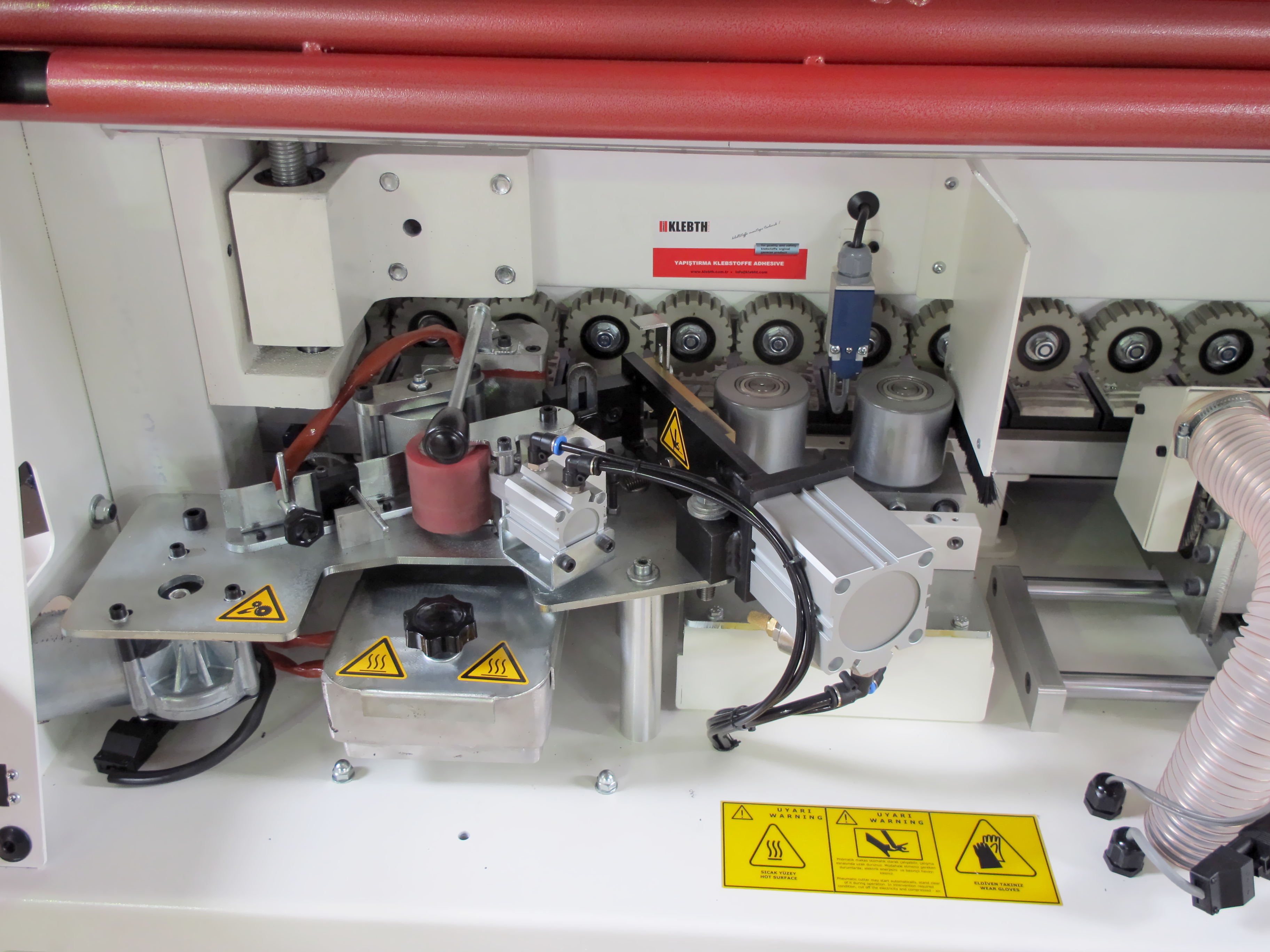

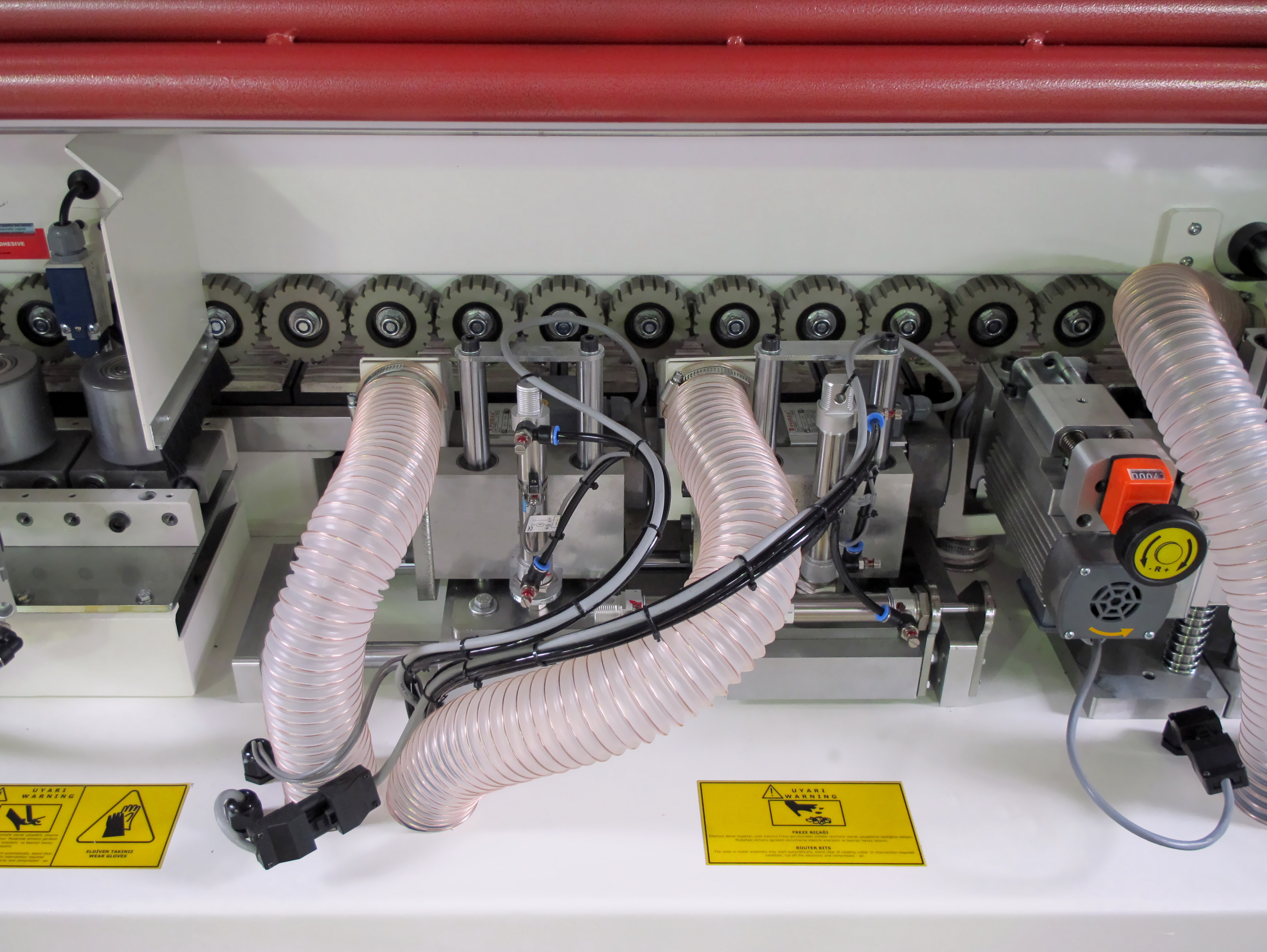

- Heavy duty feed system by chain track and upper pressure rollers

- Wide glue pot

- Easy to adjust glue thickness application

- Automatic tape infeed

- Automatic tape guillotine

- Independent front and back trimby saw blade (2 motors)

- Top and bottom combi flush trim

- Top and Bottom Buffing

- Lift up safety cover with internal lighting

Specification

|

Specification |

|

312S |

412S |

512S |

|

Edge Band Thickness |

0.4-2mm |

Y |

Y |

Y |

|

Panel Height |

0-48mm |

Y |

Y |

Y |

|

Feed speed |

12 m/min |

Y |

Y |

Y |

|

Standard LCD control |

|

Y |

Y |

N |

|

Colour touch screen control |

|

N |

N |

Y |

|

Tape support table |

Revolving |

Y |

Y |

Y |

|

Adjustable infeed fence |

Stock removal for pre milling |

N |

N |

Y |

|

Safety Limiter |

Prevents over feeding |

Y |

Y |

Y |

|

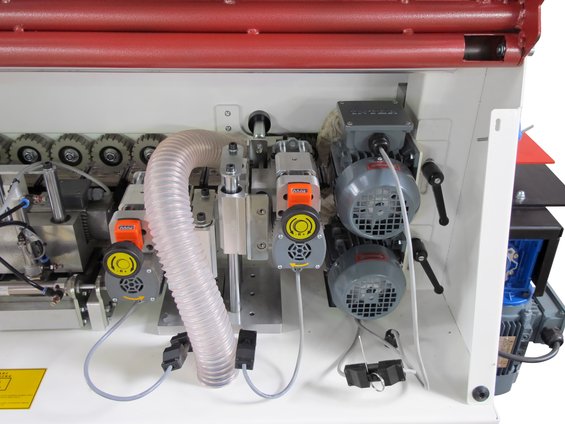

Pre milling |

2 x 1.8 Kw, 10,000 RPM |

N |

N |

Y |

|

Automatic tape infeed |

|

Y |

Y |

Y |

|

Heavy duty guillotine |

To cut from coil |

Y |

Y |

Y |

|

Pre heating of the edge |

|

N |

N |

Y |

| Front and rear end trim saws | 2 x Motors | Y | N | N |

| Top and bottom flush trim | 2 x Motors | Y | N | N |

|

Multi function trimmers |

2 x 0.55 Kw, 12,000 RPM |

N |

Y |

Y |

|

Scrapers |

Top and bottom |

N |

Y |

Y |

|

Solvent cleaners |

Top and bottom |

N |

Y |

Y |

|

Buffers |

Top and bottom |

Y |

Y |

Y |

|

Lateral Support rail |

For large panels |

Y |

Y |

Y |

|

Acoustic safety enclosure |

With lighting |

Y |

Y |

Y |

|

Integrated dust blower |

|

Y |

Y |

|

|

Heat up time |

Circa 30 mins |

Y |

Y |

Y |

|

Glue tank capacity |

Kg |

1.8 |

2.5 |

2.5 |

|

Air Pressure |

5 Bar |

Y |

Y |

Y |

|

Power Requirement |

KW |

4.2 |

6.5 |

9.5 |

|

Net Weight |

KG |

500 |

750 |

900 |

|

Working Height |

mm |

900 |

930 |

930 |

|

Length |

mm |

2860 |

3500 |

4250 |

|

Width |

mm |

970 |

1000 |

1000 |

|

Height |

mm |

1300 |

1500 |

1500 |